i-Scheduler, the intelligent production scheduling automation solution

i-Scheduler is an intelligent production scheduling automation solution that combines reinforcement learning AI and process simulation technology.

By automating production scheduling, which were previously manual tasks carried out using Excel, the solution supports agile production planning that can quickly adapt to the complexities of rapidly changing supply chain environments.

Through sophisticated simulation modeling, it minimizes the risk of applying the solution to the field and quickly identifies anticipated problems to establish an optimal production schedule.

It enhances production scheduling reliability for small and medium-sized manufacturing companies to over 90%, optimizing the efficiency of the production process and facilitating the adoption of smart manufacturing practices.

-

1

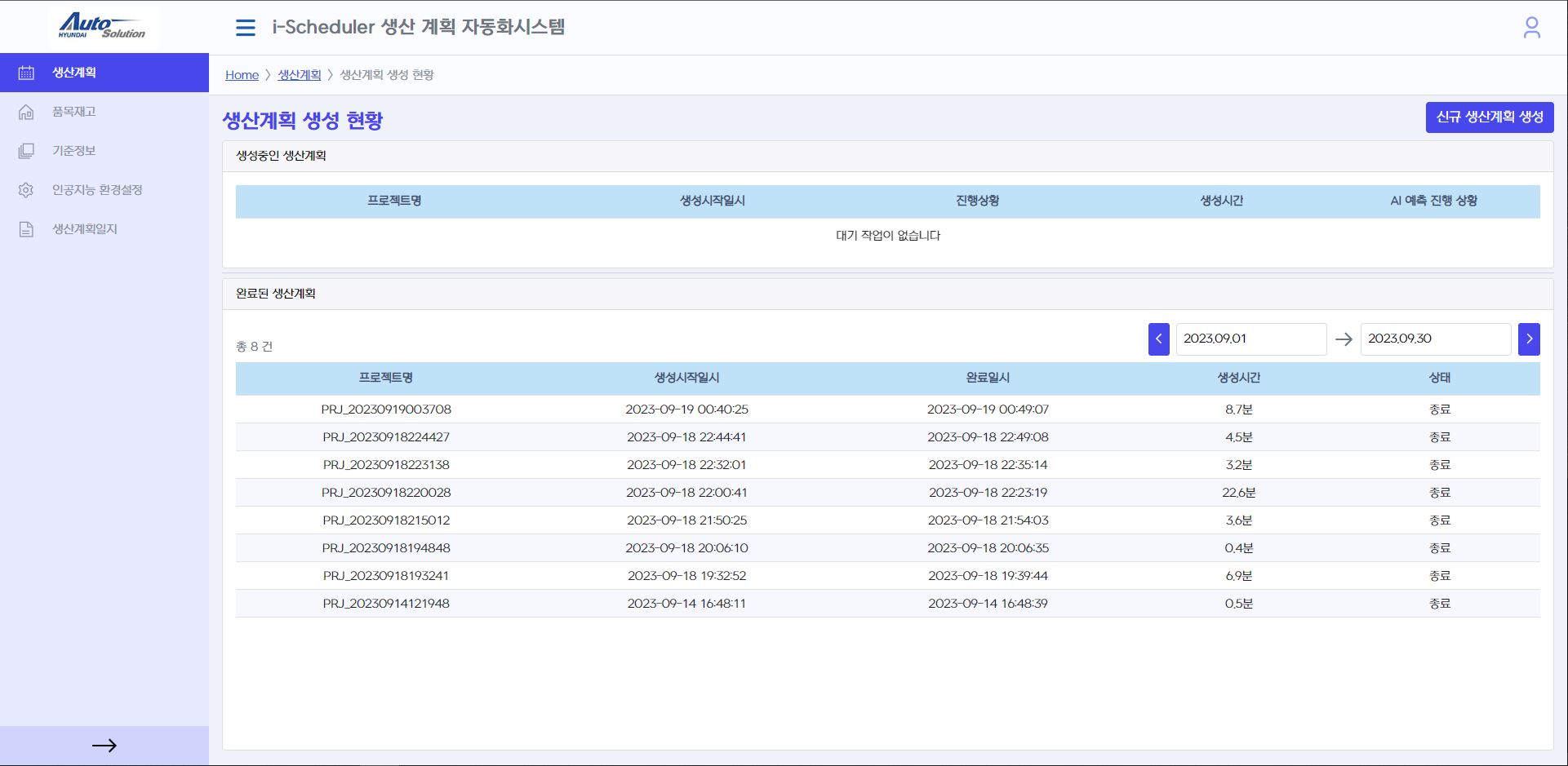

Automatically generate production schedules to keep inventory in stock and respond to urgent orders

-

2

Automatically recommend out-of-stock items, support manual item configuration, and facilitate production order assignment

-

3

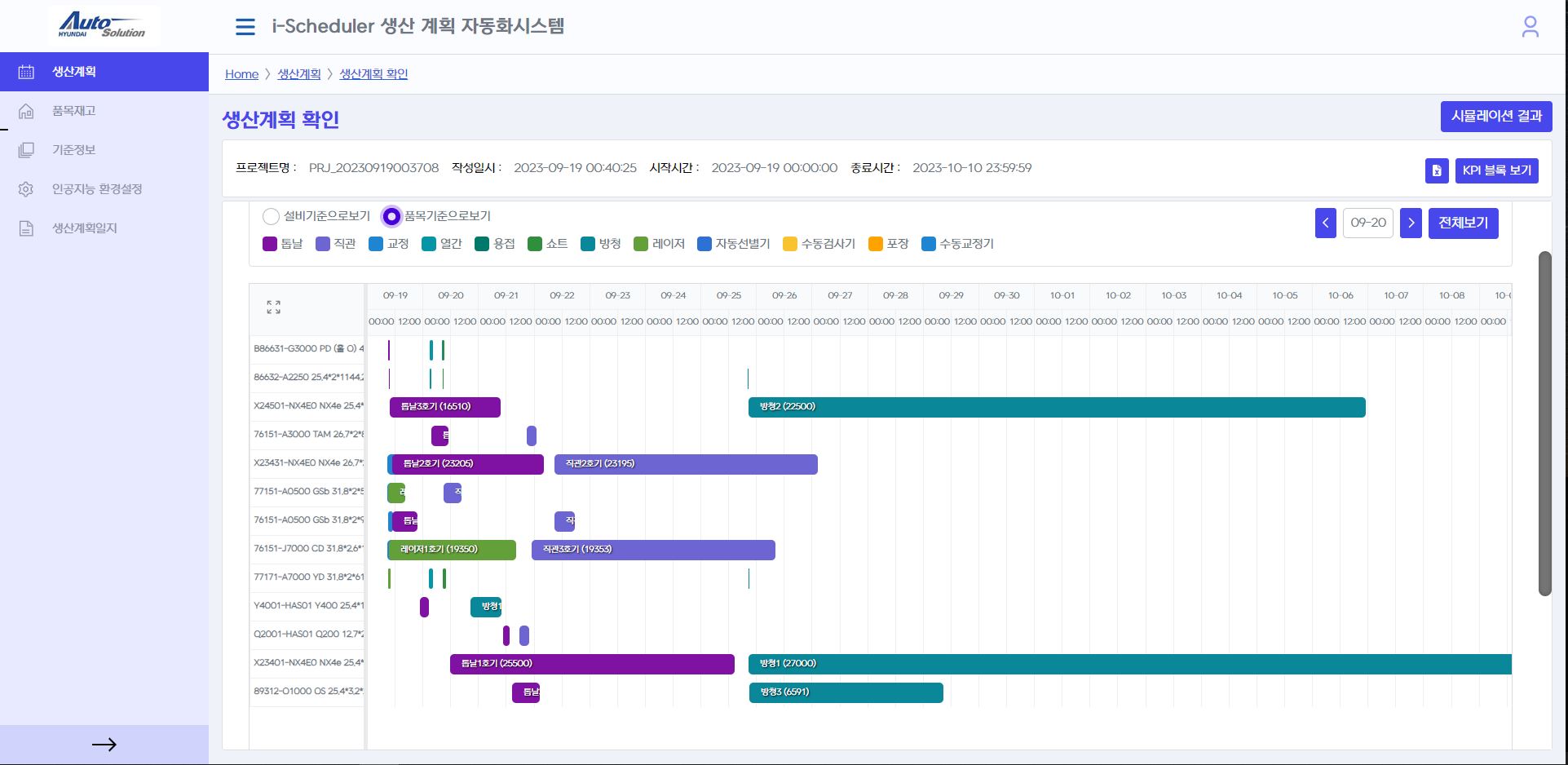

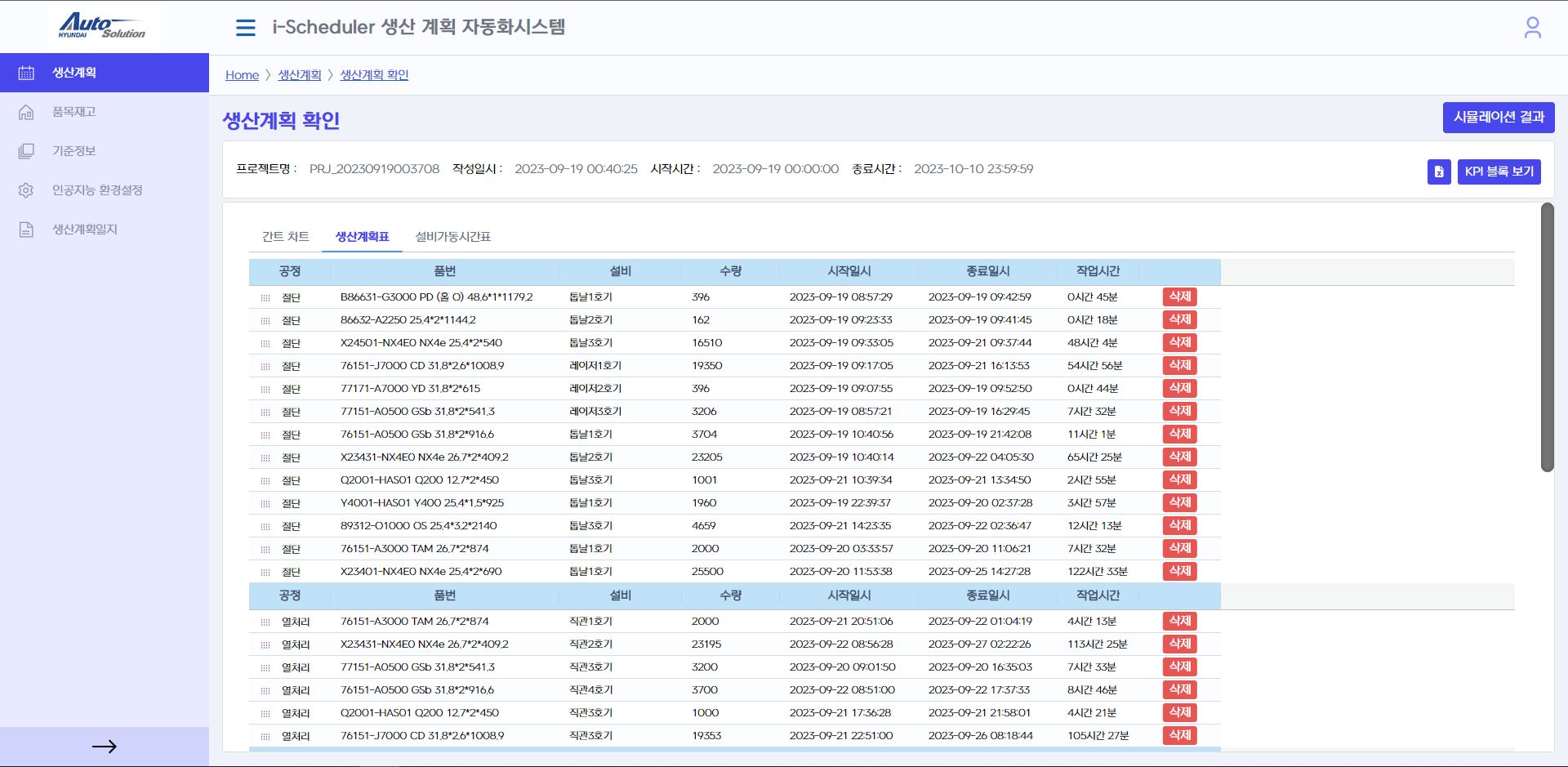

Represent production schedule in Gantt chart format

-

4

Support modification of AI-generated production schedules and regeneration of scheduling

-

5

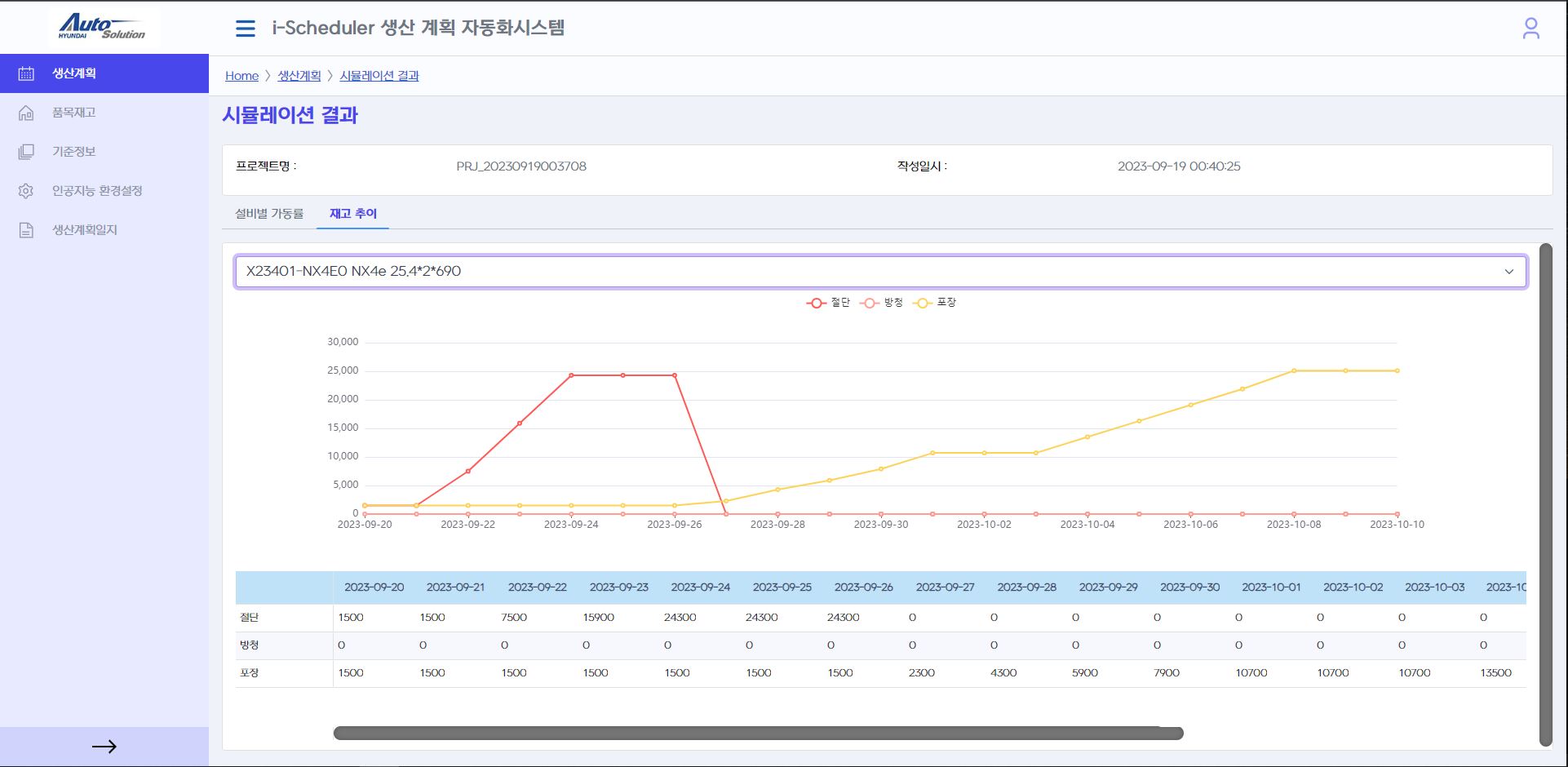

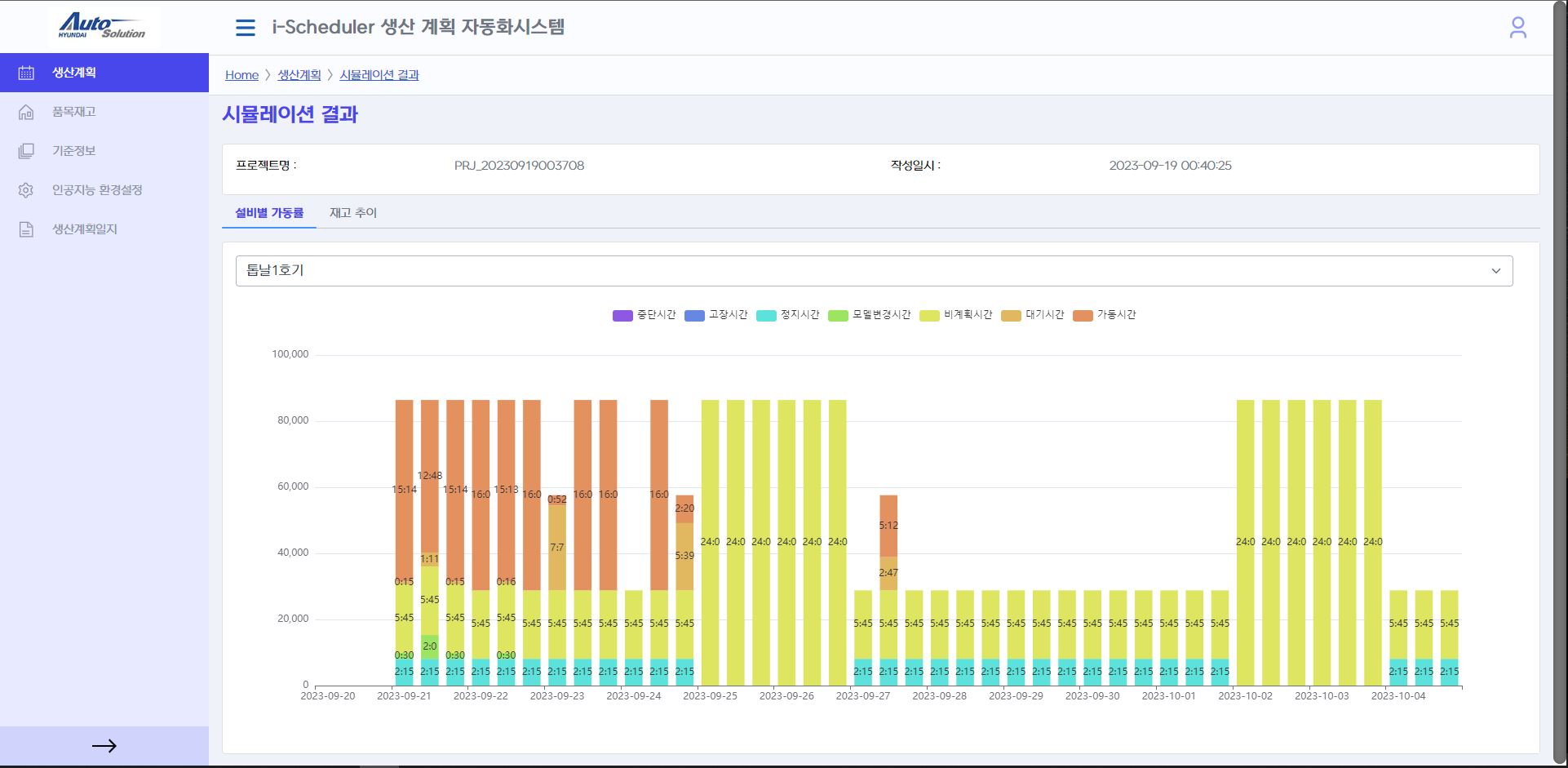

Predict daily equipment operation and item inventory trends through simulation

- 1

Adapt efficiently to dynamic internal and external manufacturing environments

- 2

Enable smooth scheduling even in the absence of skilled labor, due to user-friendly features designed for operator convenience

- 3

Accelerate the digital transformation of the company and continuously upgrade intelligence by accumulating and analyzing production data

- 4

Affordable deployment and operation costs for customer size

Enhance actual productivity gains and ensure on-time delivery through a highly reliable production scheduling

Enhance actual productivity gains and ensure on-time delivery through a highly reliable production scheduling Boost net profit by minimizing labor costs, reducing manual errors, and reducing the risk of overproduction

Boost net profit by minimizing labor costs, reducing manual errors, and reducing the risk of overproduction Increase employee satisfaction through optimization of working hours

Increase employee satisfaction through optimization of working hours

- Manage master data for production planning and integrate external data

- Provides APIs for integration with external systems such as ERP and MES

- Provide simulation model environment to manage multiple scenarios

- Simulation scheduling with Virtual Factory

- Create optimal production schedule with reinforcement learning model

- Create optimal schedule for target safety stock with inventory fluctuation trend

- 1

Manufacturing companies pursuing company growth through digital transformation

- 2

Manufacturing companies where a small number of highly skilled workers manually create production schedules

- 3

Manufacturing companies experiencing significant changes in internal and external production environments (supply chain, etc.)

- 4

Manufacturing companies that want to digitize the company's experience and knowledge and internalize the information