Automatically generate

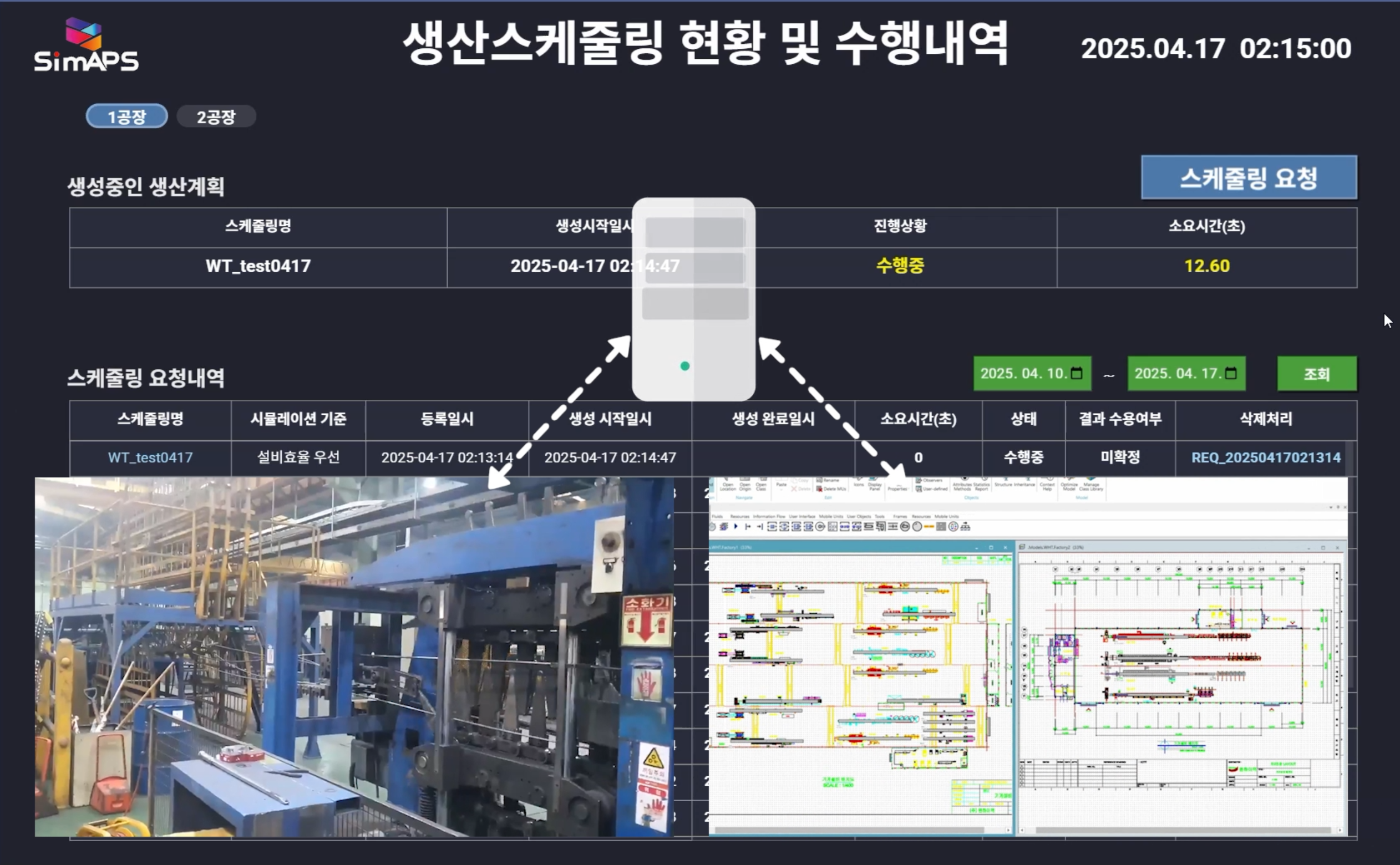

executable production schedules – SimAPS

In a virtual factory powered by Siemens Plant Simulation, SimAPS creates constraint‑aware, due‑date‑driven schedules and validates them via simulation for high plan reliability.

SimAPS at a Glance

Automatic scheduling with capacity/setup/inventory/due‑date constraints

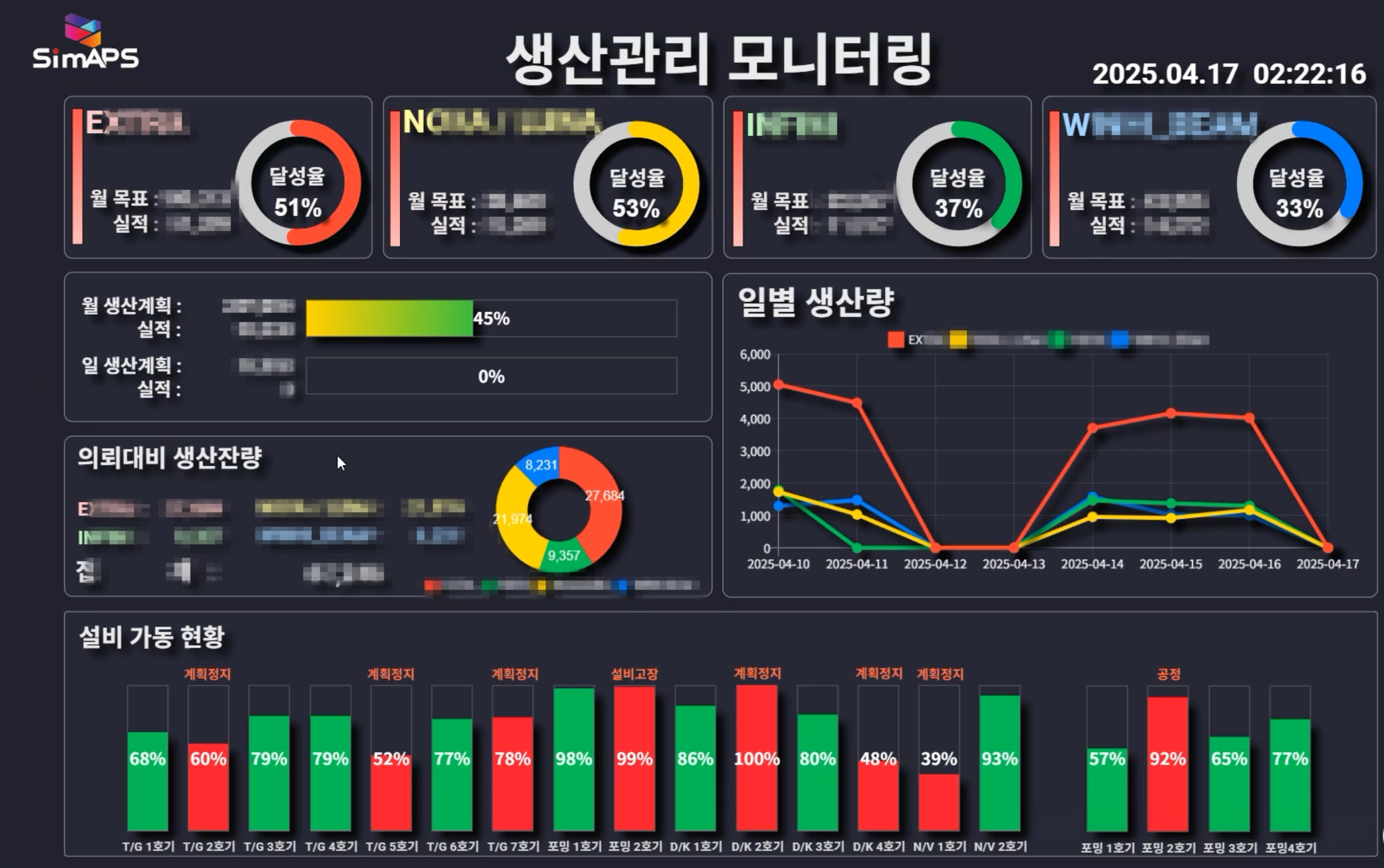

Simulation validation to forecast utilization, WIP and inventory trends

Visualization – Gantt, resource load, inventory charts

Interactive planning – manual edits, partial recalculation, scenario compare

What is SimAPS?

A simulation‑based APS platform combining discrete‑event simulation and AI optimization to automatically generate executable production plans.

Designed for Planners

Gantt editing, locks & priorities, and partial rescheduling reflect real‑world operating practices.

Fast Adoption

Modular packaging makes it practical for SMEs to roll out step by step.

Key Features

Automatic Schedule Generation

Integrates ERP/MES data and respects capacity, setup, inventory and due‑date constraints.

Simulation Validation

Runs the schedule in a virtual factory to forecast utilization, WIP and inventory.

Visualization & Editing

Gantt, resource‑load and inventory charts, manual tweaks, partial recalculation, scenario comparison.

AI + Heuristic Optimization

Targets due‑date adherence, lower WIP & inventory, and higher equipment efficiency.

What‑if Experiments

Assess policy changes: shift patterns, new machines, setup rules and more.

APIs & Integration

REST APIs enable two‑way integration with ERP/MES/PLM and other systems.

Benefits

Higher Due‑Date Performance

Executable plans reduce schedule breaks and improve delivery reliability.

Better Utilization

Identify bottlenecks and optimize setup policies to boost throughput.

Lower WIP & Inventory

Optimize flow to reduce working capital and stockouts/overstocks.

Standardized, Automated Planning

Minimize manual errors and institutionalize data‑driven decision making.

Technical Architecture

Data Layer

ERP/MES/PLM integration, master & transactional data ingestion and consistency management.

Data PipelineSimulation Engine

Process/resource models in Siemens Plant Simulation to validate execution feasibility.

Virtual FactoryOptimization Engine

Reinforcement learning plus heuristics/mathematical methods to optimize KPIs (due‑date/WIP/inventory/utilization).

AI SchedulingApplication Layer

Gantt/load/inventory views, interactive editing, scenario management, REST APIs.

UI · APIWho It's For

High‑Mix, Low‑Volume

Frequent priority changes, constrained resources, and heavy setup overheads.

Complex Process Constraints

Precedence, parallelism, and bottleneck‑rich manufacturing environments.

DX / Smart Factory Transition

Organizations moving from spreadsheet planning to automated, data‑driven workflows.

Why SimAPS

Simulation‑based APS – validate algorithmic schedules for real‑world executability.

Field‑proven – validated across multiple industries (construction materials, auto parts, batteries, logistics, etc.).

Extensible – modular architecture to adapt to company‑specific needs.

Easy to adopt – phased rollout with training and migration support.

Product Screens / Gallery (Placeholder)

Replace the blocks below with screenshots or demo GIFs.

Contact Us

Leave your info and we'll reach out with a demo and adoption guidance.